Metallurgical Failure Analysis

Metal fracture symptomatic of a problem - unfavorable stresses and strains, improper heat treatment, metallurgical flaws, improper design or perhaps a device simply has exceeded its useful service life. Initiating corrections is based upon a proper diagnosis. Reading and understanding the fracture surface, evaluating the alloy microstructure and studying a component’s performance represent a few of our analytical tools. Completion of a project occurs when our clients receive a clean and succinct report of the technical findings.

Recent Projects

Rig Collapse

Investigation revealed that the weld failure was a consequence of an indirect overload on the rig mast.

Drilling Tool

Fatigue fracture caused failure of this special drilling tool. Poor overlay of hardfacing material induced fatigue cracking very early in its lifetime.

Tubing Fracture

Longitudinal tubing split - the joint was dropped downhole. No Material defects were discovered and the properties satisfied API specifications.

Tank Battery Degradation

Degradation of a tank battery catwalk.

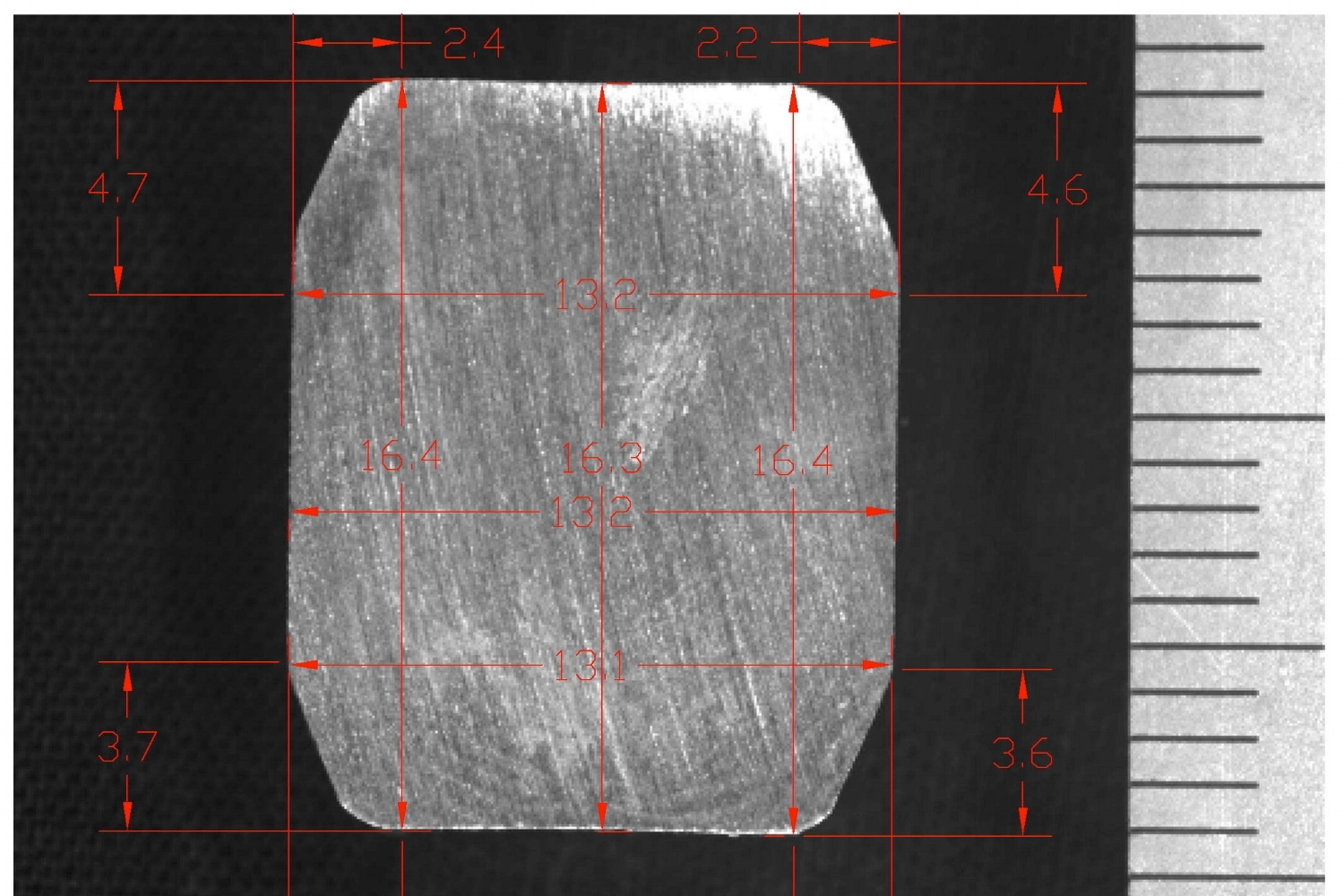

Mystery Gasket

Profile of a stainless steel ring gasket. Dimensions beyond the cited tolerance lead to improper seating.